This article was written by Joe Mangiardi and originally appeared on NESGlobal.net on July 8, 2019.

Marijuana Industry Hazards: The Next Chapter

Recent publications indicate that marijuana industry hazards are more numerous and varied than many might have expected. Marijuana is now legal in some form (medical and/or recreational) in more than half of U.S. states, but the industry has yet to develop as a full-fledged, law-abiding entity operating under the same occupational health and safety considerations and other regulatory compliance mandates as those expected to be adhered to by businesses in more well-established industries.

In a March 29, 2018 blog entitled Marijuana Industry Health and Safety: The Next Step to Legitimacy, NES summarized findings from a Colorado State University study of Colorado marijuana industry workers. The study and associated report revealed that quite often little to no concern was given to proper training for employees regarding hazards inherent to the industry. This article is dedicated to describing those hazards in greater depth and detail.

Recognizing Marijuana Industry Hazards

To address the need to identify and meaningfully appreciate the significance of marijuana industry hazards, the Colorado Department of Public Health & Environment assembled a committee of subject matter experts. This committee, called the Colorado Marijuana Occupational Health and Safety Work Group, comprises epidemiologists, medical doctors, industrial hygienists, safety professionals, and regulatory specialists. Together these individuals worked to create a publication designed to help marijuana industry employers understand the hazards inherent to industry operations and, ultimately, to construct viable occupational health and safety programs to protect their employees. Published January 2017, the resulting Guide to Worker Safety and Health in the Marijuana Industry (Guide) is perhaps the most comprehensive document released to date on the topic and is the primary source of the content in this article.

It should be noted, however, that the Guide is not intended to cover all pertinent occupational health and safety regulations, nor does it include new legislation enacted specifically for the marijuana industry. These efforts reflect a work in progress; the Colorado Marijuana Occupational Health and Safety Work Group explicitly states that its intention is to continue to meet and improve the information in the Guide.

Breaking Down Marijuana Industry Hazards

Many of the hazards that can be found in the marijuana industry are the same as those known to be present in workplaces throughout many industries. It is therefore important to understand that, while the particulars may be unique, drawing attention to what differs about the marijuana industry is not the goal of articles such as this; rather, the purpose is to reveal and explore the commonalities. These hazards are hazards just like those in any other industry and, as such, must be appropriately identified and managed.

Marijuana industry hazards can be broken down into three main categories: biological, chemical, and physical.The following sections will present some of the most common sources of hazards in the marijuana industry separated into these three categories.

Biological Marijuana Industry Hazards

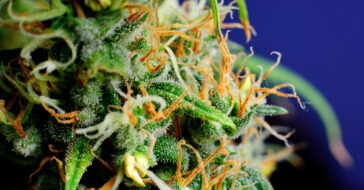

Biological hazards are associated with direct contact with marijuana plants. Bacteria and fungi can cause respiratory issues, eye, skin, and throat irritation, nasal congestion, and other adverse health effects.

Mold

Employees who cultivate and/or trim marijuana may be susceptible to mold exposure. This is due in large part to the high humidity levels required for marijuana production—sometimes as high as 70 percent. This can lead to mold growth, and mold spores in the air can cause wheezing, coughing, trouble breathing, respiratory infections, and exacerbation of asthmatic conditions. It may be necessary to enlist the services of an industrial hygienist to perform air monitoring to assess mold spore levels in the areas where employees will be working. If necessary, workers may have to wear personal protective equipment (PPE).

Controlling moisture is extremely important in limiting mold growth. Standing water contributes to humidity levels, so proper irrigation can help limit accumulation. Engineering controls such as increasing ventilation or switching from sweeping to vacuuming for cleanup can also help to combat mold exposure.

Sensitizers/Allergens

Itchy skin, hives, and swollen, irritated eyes can result from direct contact with marijuana plants. Some individuals are allergic or hypersensitive to the plant, and reactions can worsen with repeated exposures.

If eliminating exposure altogether is not possible, then ventilation, job rotation, and PPE can be helpful alternatives.

Chemical Marijuana Industry Hazards

Chemicals present numerous health and safety hazards throughout virtually every profession, so it should be of no surprise to find many such instances in the marijuana industry. To keep employees safe in the workplace, information about any potentially harmful substances must be provided to workers in a way that can be easily accessed and understood. The most common methods of achieving this are through training and by making chemical product information, usually via Safety Data Sheets (SDSs), readily available to employees.

Carbon Dioxide

For marijuana industry employees who work in cultivation, carbon dioxide (CO2) may be encountered. CO2 is used in liquid gas or dry ice form to increase plant growth and during the extraction process to produce concentrates (CO2 as compressed gas stored in a cylinder may also present a physical hazard and is described in the following section). CO2 is a simple asphyxiant, meaning that it can displace oxygen at high concentrations. CO2 exposure can cause symptoms such as headache, dizziness, rapid breathing, and increased heart rate; in extreme cases, unconsciousness and death can result. This is why facilities that manage CO2 commonly have monitoring devices.

Marijuana industry employers must therefore be aware of the health and safety hazards presented by CO2 and the importance of installing monitors and keeping them properly maintained and calibrated. Dry ice should never be used in small and/or confined spaces and should be handled with proper PPE, such as gloves and safety glasses. It is also necessary to train employees on the effects CO2 can have on an individual’s health so that signs and symptoms of CO2 exposure can be effectively recognized.

Carbon Monoxide

Marijuana workers cultivating the plant may be exposed to carbon monoxide (CO) in their operations, and any employees in areas where generators or other gasoline-powered equipment are being used (without adequate ventilation) may be at risk for elevated levels of exposure. Other sources include water heaters, compressors, fork lifts, floor buffers, and space heaters. CO is an odorless gas that interferes with the blood’s ability to carry oxygen throughout the body. The danger is that high concentrations of CO can overwhelm a person without warning, causing neurological damage, illness, coma, and even death.

As with CO2, CO monitors are a necessity when operating equipment that produces CO. A ventilation system that can remove CO from the work environment can be highly effective. Using alternatives to gasoline power whenever possible, such as equipment powered by electricity or compressed air, can eliminate sources of exposure. As with all matters of employee health and safety, it is important to provide employees with training covering the causes and symptoms of CO poisoning.

Indoor Air Quality

All employees working indoors are affected by a poor indoor air quality environment. Marijuana cultivation produces ozone from the chemical reaction of nitrogen oxides and volatile organic compounds, such as terpenes that are given off from the marijuana plant. According to the Guide, “Terpenes and nitric oxides are associated with eye, skin and mucous irritation. . . . Ozone can cause decreased lung function and/or exacerbate pre-existing health effects, especially in workers with asthma or other respiratory complications. More research is needed to characterize potential exposures to ozone, nitrogen oxides, and volatile organic compounds in marijuana cultivation operations.”

The key, as mentioned above, is in proper ventilation. It is recommended that HVAC systems be of the proper size and adequately maintained. PPE in the form of respiratory protection may still be needed in certain places, so it is important to know the areas of concern.

Pesticides

Facilities that grow marijuana commonly use insecticides and fungicides, and some pesticides carry certain skin and respiratory hazards. Anyone who cultivates or harvests marijuana, mixes, loads, or applies pesticides/fungicides, or cleans or repairs equipment used in the process of applying pesticides/fungicides is affected. Federal law under 40 CFR Part 170, also known as EPA’s Agricultural Worker Protection Standard, sets forth certain requirements intended to reduce the risk of employee poisoning from pesticides.

Employees applying pesticides/fungicides must not do so without being aware of the associated toxicity specifications listed on the manufacturer’s label; if necessary, proper PPE should be worn to protect against exposure. This can be aided by keeping on hand the relevant Safety Data Sheets. Additionally, containers holding pesticides/fungicides should be labeled with the name of the product, active ingredient, EPA registration number, and all applicable human hazard signal words.

Disinfectants and Other Cleaning Chemicals

While these hazards may seem to be common knowledge, employees must be warned of the potential hazards of all cleaning agents used at the workplace—even common household cleaners. When even basic cleaning agents are used on a regular basis they can cause skin irritation or respiratory issues. Injuries due to spills and splashes can also occur.

Chemicals should be selected as appropriately as possible based on the specific microorganism(s) intended to be eliminated. Basic hazard communication (right-to-know) safety training should be conducted so that employees are aware of the hazards of the chemicals kept at their facility and basic facts such as never to mix bleach with ammonia. Safety Data Sheets should be kept and cleaning agents labeled appropriately.

Nutrients and Corrosive Chemicals

Employees who work cultivating marijuana plants and those who mix plant nutrients may encounter corrosive chemicals used for plant growth. These corrosives can be so potent that they can even damage or destroy metal. The chemicals can irritate or burn the eyes and can present respiratory hazards if their vapors are inhaled, burning the inner lining of the nose, throat, and lungs.

Most corrosives are either acids or bases—acids and bases should never be mixed. Further considerations must also be noted concerning storage, such as making sure not to store acids on metal shelves or with water-reactive metals. Proper training should be provided, and PPE should be worn when handling corrosive chemicals. Employers must also provide areas to wash up and emergency eyewash stations.

Physical Marijuana Industry Hazards

Of all the hazard types, the marijuana industry shares more physical hazards in common with other industries than any other category of hazard. Many of these hazards can be found in almost every workplace, and, while attention to the proper management of all physical hazards is always critical, focus in this section will be on those hazards most specific to the marijuana industry. Others will follow in list form.

Compressed Gas

As mentioned in the above description of CO2 hazards, compressed gas in highly pressurized cylinders can often be found at marijuana cultivation and extraction facilities. Compressed gas cylinders are hazardous because of this high pressure. Most cylinders have safety-relief devices designed to prevent rupture in the case of excessive pressure buildup, but a broken or leaking valve can be extremely dangerous. Cylinders exposed to fire or extreme heat are at risk for explosion.

Cylinders must be stored upright, properly chained, and kept at the appropriate temperature. When not in use, cylinder caps must be in place. SDSs on the gases being used at the facility should be available, and employees must be properly trained.

Ergonomics

Employees whose job duties involve trimming marijuana leaves or other cultivation tasks requiring awkward, repetitive postures, motions, and/or lifting will be affected by ergonomics concerns. It is the responsibility of the employer to provide a safe and healthful work environment for employees, and this includes conducting worksite analyses to identify all working conditions that may adversely impact workers over the long term.Various musculoskeletal and stress related disorders can develop if working conditions are not modified to reduce the impact of these activities.

It is recommended that employers communicate clear ergonomics-based policies with employees. Development and implementation of an effective, ergonomically sound work plan can include such elements as delegating responsibilities to designated employees, employee job rotation, ensuring proper staffing, installing conscientiously constructed work stations complete with anti-fatigue mats, providing proper tools in a range of sizes, and encouraging the early reporting of any musculoskeletal disorders.

Electrical

Marijuana grow operations require a great deal of energy. This translates to hazards in many forms: “temporary wiring (e.g., extension cords), missing breakers, blocked electrical panels, improperly wired units, electricity use in high humidity and watering areas, improper repairs, unguarded fans, overloaded circuits, inadequate wiring, lack of training and general electrical safety” (Guide). Beyond these electrical hazards listed in their routine operational states, employers are further required to protect employees from hazardous energy sources on equipment during maintenance and repairs (lockout/tagout).

There are numerous best practices that should be adhered to for the safe management of potential electrical hazards. An electrical safety program should be implemented and should consider proper bonding and grounding of cables, overcurrent protection, electrical guarding, and installation and use of electrical cords and wiring in wet/humid locations, among other safety considerations. Extension cords should only be used as designed, electrical equipment should be inspected before use, and defective equipment should be removed from service. Instruct employees not to stand in wet areas when using electrical equipment. A written lockout/tagout program should be developed and complemented by initial and annual training.

Lighting

Employees working around metal halide lights, which emit ultraviolet (UV) radiation, are at risk for photokeratitis, a painful eye condition that can result from exposure to UV rays. If the outer bulb of a halide light is broken, photokeratitis can occur several hours following exposure. Symptoms include tearing, blurry vision, and the sensation of having a foreign object in the eye. UV lamps can be used as germicidal tools, but exposure can cause ocular inflammation and tearing and can also result in sunburn-like effects on the skin, which are exacerbated by certain medications. Additionally, fluorescent lighting is often used in marijuana cultivation facilities, presenting hazards when the bulbs break or are damaged. Lead, cadmium, and mercury, which are toxic to humans, are commonly utilized in the composition of fluorescent bulbs, and these metals can be inhaled as vapors when the bulbs are broken.It is critical that employees know how to properly dispose of these items (classified as “universal waste”).

Marijuana industry employers whose operations feature UV and/or dangerous metals-containing lighting are encouraged to consider alternative options. If such options are not feasible, employees must wear appropriate PPE. If a bulb is broken or spent, proper fall protection safety measures must be taken when replacing the item. All bulbs and lighting fixtures must be installed and operated in strict accordance with manufacturer specifications, and used and broken lamps/bulbs must be labeled and disposed of properly. Protocols should be developed for the safe cleanup and disposal of used and broken lamps/bulbs.

Extraction Equipment

Few other industries engage in processes similar to the plant oil extraction for which the marijuana industry is known. High heat and pressure are used in the extraction process, creating fire and explosion hazards. Extraction typically involves the use of high-pressure machinery, butane, CO2, and/or flammable/combustible liquids, all of which are hazardous.

Local fire codes must be followed, and a fire protection policy plan should be established. Employees performing extraction operations must be properly trained and must wear appropriate PPE. All electrical equipment and other components used in the extraction process must be operated as specified by the manufacturer and in accordance with applicable electrical standards. The extraction rooms should be dedicated specifically to extraction, and these rooms should meet state and local fire code regulations. As marijuana related legislation is gradually developed and codified, regulations will likely change—stay apprised of regulatory developments in your area.

Other Physical Hazards

These hazards may be present in marijuana industry workplaces and are generally found in many work environments:

- Flammable/Combustible Liquids

- Occupational Injuries

- Workplace Violence

- Walking/Working Surfaces

- Working at Heights

- Noise

- Emergencies

- Powered Industrial Trucks

- Machines and Hand Tools

- Confined Spaces

Marijuana Industry Hazards: Conclusion

Marijuana industry employers will need to consider the above listed and described hazards in designing their Safety and Health Program as well as any others that may be inherent to operations at their facility. More information about the hazards included in this article as well as information on addressing these elements when developing a Safety and Health Program can be found in the Guide.

For an additional resource on designing your Safety and Health Program, see the NES article Safe + Sound Week: Committing to an Effective Safety and Health Program.

As the marijuana industry gradually develops, policies and procedures to manage workplace hazards will evolve along with it. What is important is to recognize the dangers present in marijuana industry workplaces as soon as possible and to strive to address those issues. Doing so will prevent injuries and illnesses that could otherwise have been avoided.

NES is doing just that with training programs designed for those who will be involved in the marijuana industry. To learn more, see the associated article Marijuana Industry Health and Safety: The Next Step to Legitimacy. If you have questions about marijuana industry hazards, marijuana-based environmental health and safety training, and/or industrial hygiene services with NES, please contact us at 916-353-2360 / 800-637-2384 or via email at office@nesglobal.net.